Secretary Duffy tells how to get it done on Fox TV. Yesterday, the U.S. Department of Transportation notified the California High Speed Rail Authority that it intends to claw back roughly $4 billion in federal funds for the Los Angeles – San Francisco high-speed line....

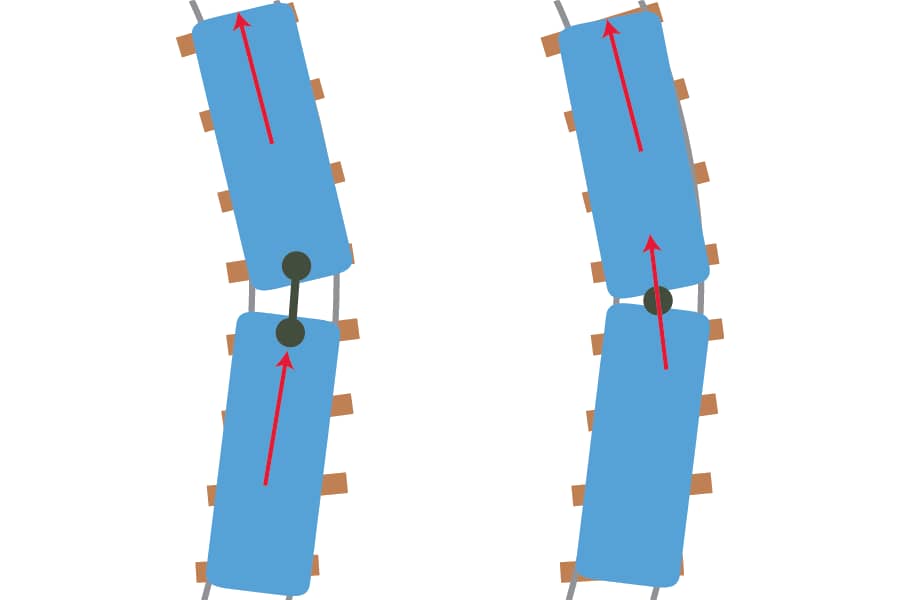

Articulated Trains

Articulated trains, in which passenger cars share “trucks” (wheel and axle assemblies) with the adjoining cars, improve average speed, passenger comfort and safety. While this configuration sacrifices some capacity per train length and results in higher axle loads, it provides advantages on rough, heavy-haul freight track.

Faster Through Curves

With individual cars, whether they are independently coupled or semi-permanently coupled, each car rides through a curve with independent motion, exerting its own forces against the outer rail.

Shared trucks lessen lateral stresses on the roadbed as each car pulls the following car through a curve. The result is higher speeds through curves.

Compared to traditional car designs (left), articulated trains that share wheels between cars (right) allow faster speeds on curves and ride smoother on rough track.

Lighter Weight

Railroad wheels are heavy. A single 36-inch rail wheel can weigh more than a ton.

Shared trucks reduce the number of wheels and the weight of the train, letting trains accelerate faster and reducing wear on the track.

Comfort

The articulation joints cause the ride to be much smoother because each car isn’t bouncing around on its own.

Because the car ends do not hang over the truck, the effective width of the train through curves is reduced and articulated trains can be as much as 8” wider than conventional trains for the same track and tunnel profiles. This allows for wider aisles and seats, improving comfort.

Tell Congress That You Want Fast, Frequent and Dependable Trains.

Let’s make high-speed rail a reality

The Latest from HSRA

Our Latest Blog Posts

Check out the latest news, updates, and high speed rail insights from our blog!